Product feature

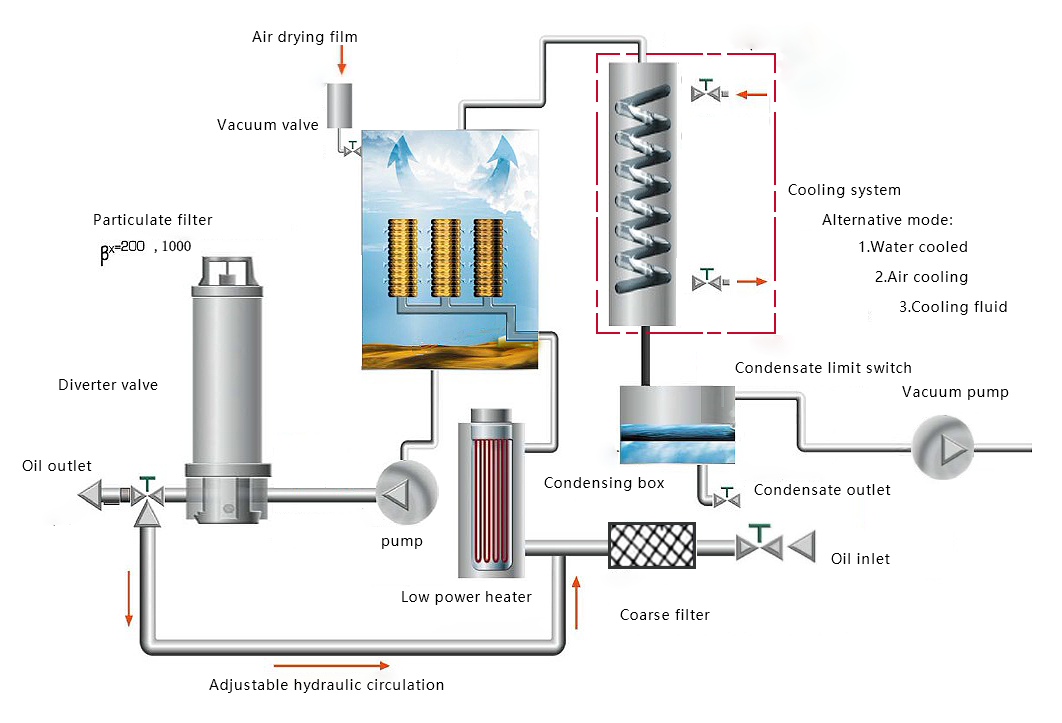

1.Unique degassing and dehydrating system, promptly separating the moisture and gas from the oil.

2.Heating system adopts the optimized pipeline design, ensuring the heating is even, the oil temperature is stable.

3.Automatic constant temperature control system, automatic liquid level control system, automatic defoaming control system, automatic pressure protection system and excellent configuration, ensuring the equipment can be operated in a high-performance environment.

4.Precise filtration system with large capacity of holding pollutants, rapidly removing the mechanical impurities in the oil, equipped with the function to automatically detect the pollution level.

5.Personalization design, low noise, easy operation, long interval of maintenance time, low energy consumption, saving operating costs.

6.Online oil filtration, without any operators on duty, operation state shows from guiding lights.

7.Equipped with filter element replacement indicator, and saturated downtime device.

8.Equipped with electric leakage, overload downtime unit, protecting the electric motor.

9.Equipped with phase sequence, phase loss protection device, security control to prevent from drop-dead halt.

Get a quate

Get a quate

Online consultation

Online consultation